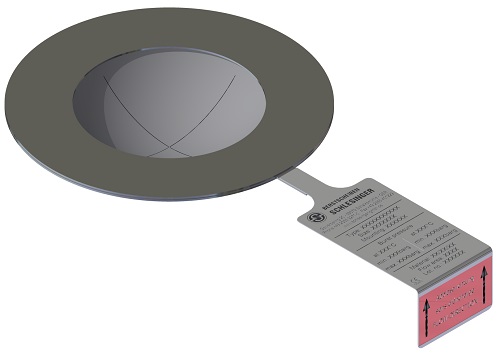

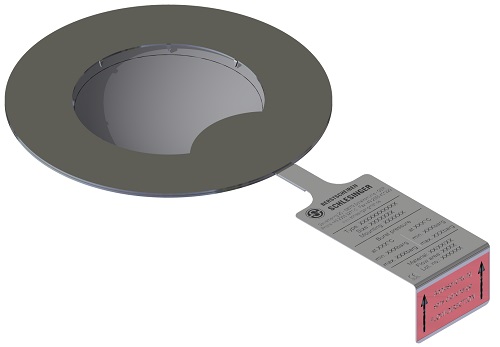

Reverse buckling bursting discs

(Reverse buckling rupture disks)

Reverse buckling bursting discs are scored, full metal components of nickel, nickel-based materials (Inconel, Hastelloy)* or stainless steel. They are mainly used in processes with medium and high pressures, high operating temperatures and considerable pressure fluctuations. The principle of the Euler buckling pin is used: reverse buckling bursting discs are domed opposite to the pressure direction. Upon reaching the burst pressure the dome reverses and ruptures along the scoring. Their special design makes reverse-buckling bursting discs very resistant against high operating pressures and alternating-pressure loads as well as high operating temperatures. The longer service life of the bursting discs and the associated, lower expenses for downtimes, maintenance and replacement bursting discs are advantages our customers appreciate.

Berstscheiben Schlesinger produces reverse-buckling bursting discs in two versions: cross-scored (Type UX) or round-scored (Type U) discs in standard sizes from DN 15 to DN 300. They can withstand pressures between 1 and 400 bar and temperatures between minus 50 and plus 450 degrees centigrade. Customised versions with varying materials, pressures and dimensions are also on offer. Our reverse buckling bursting discs are mounted in a holder or directly between clamp sockets. Furthermore we have versions with burst monitoring that can also be used in explosion-protected areas. Reverse buckling bursting discs are used for their excellent properties for example in reactors, pressure vessels and gas cylinders either as sole pressure protection or in combination with a safety valve. In the latter case, the bursting disc protects the valve against corrosive or adhesive process media that would render the valve unusable. This facilitates the use of cost-efficient valves and lower maintenance costs.

Your benefits at a glance:

- individual product specification for material, pressure and dimension

- suitable for medium and high pressure

- high corrosion and temperature stability as well as resistance to alternating pressure loads

- fully vacuum resistant and gas-tight due to solid-metal construction

- lowest leakage rates

- with integrated burst detection available

*Inconel and Hastelloy are a registered trade names

Continuing links

Do you have any questions or need a non-binding offer?

Our contact persons will be glad to assist you.